Silicon Carbide Applications

Silicon carbide is a typical compound of the polymorph according to the categories of points , with α- silicon carbide, β- silicon carbide two. α- silicon carbide abrasive as black , green, two varieties. β- silicon carbide is the main raw material for preparing silicon carbide ceramics class .

Extensive use of silicon carbide , such as: metallurgy , machinery, chemicals , building materials, light industry, electronics . Metallurgical Industry as abrasive cleaning agent , deoxidizer and conditioner. In terms of machining can be used as synthetic carbide cutting tools ; machined silicon carbon plate can be used as batts refractory ceramic firing . After finishing produced by powder can be used for high-tech electronic components and far-infrared radiation material coatings. Fine powder of high purity aerospace defense industry utensils available coatings . Use of international and domestic sectors of the economy is very broad.

1 , non-ferrous metal smelting industry applications

The use of silicon carbide with a high temperature , high strength, good thermal conductivity , impact resistance, high temperature for indirect heating materials, such as Kennedy Retort furnaces. Distillation oven tray, pot, copper melting furnace lining, zinc plates arc furnace , thermocouple protection tubes.

2 , the application of aspects of the steel industry

The use of corrosion-resistant silicon carbide . Thermal shock resistance to wear. Thermal conductivity and good for large furnace lining improves life.

3 , metallurgical beneficiation industry applications

Silicon carbide hardness only to diamond , with strong wear resistance , wear-resistant material is ideal for pipes, impellers , pump chamber , cyclone, ore bucket liner , the wear resistance of cast iron . 5-20 times the life of the rubber is one of the ideal materials aviation runway flight .

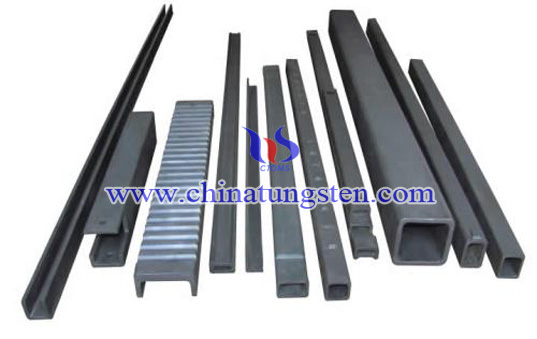

4 , building ceramics , wheel industrial applications

Use of its thermal conductivity . Thermal radiation , high strength characteristics of high fever , manufacturing sheet metal kiln , kiln furniture can not only reduce capacity, but also improve the installed furnace capacity and product quality , shorten the production cycle , baked glazed ceramic sintering is ideal for indirect materials.

5 , energy-saving aspects of the application

Use good thermal conductivity and thermal stability for heat exchangers, fuel consumption reduced by 20 % to 35% fuel savings , increased productivity by 20-30 %. Especially with the discharge conveyor mining plant put inside the pipe, which is 6-7 times the normal level of abrasion wear resistant material.

Abrasive - mainly because SiC has a high hardness, chemical stability and a certain toughness, it can be used to manufacture silicon carbide bonded abrasives , coated abrasives and grinding free , so to process glass, ceramics, stone , cast iron and certain non-ferrous metals , tungsten carbide, titanium, high-speed steel cutting tools and grinding wheels and the like.

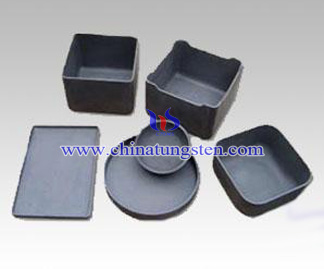

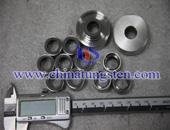

Refractory and corrosion-resistant materials --- mainly because silicon carbide has a high melting point ( decomposition temperature ) , chemical inertness and thermal shock resistance, it can be used in abrasive silicon carbide ceramics kiln firing and using the batts saggers , zinc distillation furnace industry vertical cylinder of silicon carbide brick, aluminum reduction cell linings, crucibles , furnace small pieces of silicon carbide ceramics and other materials .

Chemical Usage - silicon carbide can be decomposed as molten steel and molten steel free oxygen , the reaction of carbon monoxide and a metal oxide silicon slag. It can be used as a cleaning agent for steel smelting , which is used as a deoxidizer for steel and cast iron tissue conditioner . This is generally a low -purity silicon carbide , to reduce costs. Also as a raw material for making silicon tetrachloride .

Electrical purposes - is used as a heating element , non-linear resistance element and high temperature semiconductor materials. The heating element such as silicon carbide ( applicable to 1100 ~ 1500 ℃ various furnace work ) , non-linear resistance element , a variety of lightning valves .

Other coatings formulated into far infrared radiation made of silicon carbide or silicon plate using far-infrared radiation dryer.